Image source: ricelake.com

The process of choosing the right load cell can be complicated. There are various types to choose from and different load cell applications have unique requirements. You may even want to conduct various load cell force tests to reach a final decision. These tests use force as a variable to test materials and other complex assemblies on a wide range of parameters. Some parameters force is tested against are deflection and compaction. These tests allow you to determine the characteristics of the material and its strengths and weaknesses when in use.

A Load Cell Selection Guide

-

Understand Your Application

Look for a load cell based on the application in question.

- High Endurance Applications: for usage in an industrial setting and usually involving experimental stress. In this instance a strain gauge load cell may be best.

- Remote Applications: if the scale is in a remote setting, a hydraulic load cell could be ideal. These load cells can operate without a power connection.

- Quality Assurance and Safety Applications: pneumatic load cells deliver precise mechanical balance. This might be required for something like ensuring whether or not an IV bag is dispensing correctly or is in need of replacement.

-

Look Into Your Capacity Requirements

Determine the maximum and minimum load capacity needed for your application. To make sure you have the optimal capacity, go for a load cell that exceeds your highest operating load. Also consider the extraneous factors the load cell will be subjected to. For instance, if you use load cells in a high-endurance setting, look for a load cell with the right fatigue rating. To ensure you have the optimal load cell capacity, consider possible variances that could arise like nonlinearity, bridge resistance and hysteresis.

-

Size and Specification Requirements

Look into the size requirements of the load cell. Determine the needs of your application along the lines of:

- Height and width

- Length

- Weight

-

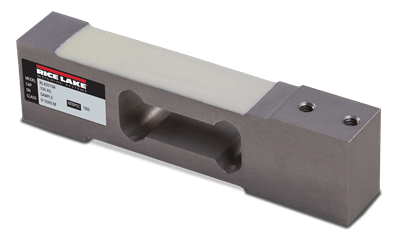

Load Cell Types

- Strain Gauge Load Cell: popular for its durability, stiffness and resonance values.

- Piezoelectric Load Cell: the piezoelectric matter in the load cell generates a voltage in response to the changing form of the load cell.

- Hydraulic Load Cell: it can be safely used in hazardous environments due to the absence of electrical parts.

- Pneumatic Load Cell: it is made to control the balance of pressure.

-

Load Cell Shapes

- S-Beam Load Cells: used mainly in applications involving tension.

- Beam Load Cells: these can be used for static weighing, dynamic weighing, silo weighing, hopper weighing, and tank weighing.

- Canister Load Cells: a popular choice for compression applications with capacity requirements of 100,000 lbs. or more.

- Pancake Load Cells: used in applications that require high precision.

- Button Load Cells: ideal for applications in confined and narrow settings. Quite popular in the medical sector.

- Thru-Hole Load Cells: designed for high stiffness and they give highly accurate results in press-load and off-centre applications.

-

Consider the Operating Environment

Consider whether the load cells will be operating in hot or cold temperatures. Check if the environment is adverse, rugged, corrosive, dry or damp. This knowledge will help you choose the right load cell for the location.

Quality Scales Unlimited has a range of load cells that can be used for many applications. For more information on selecting the load cell that will best fit your needs, contact Quality Scales Unlimited.